Out of sync adjustment for steel-strapping clip-machine

The case of out of sync from customer's request and solve it on line

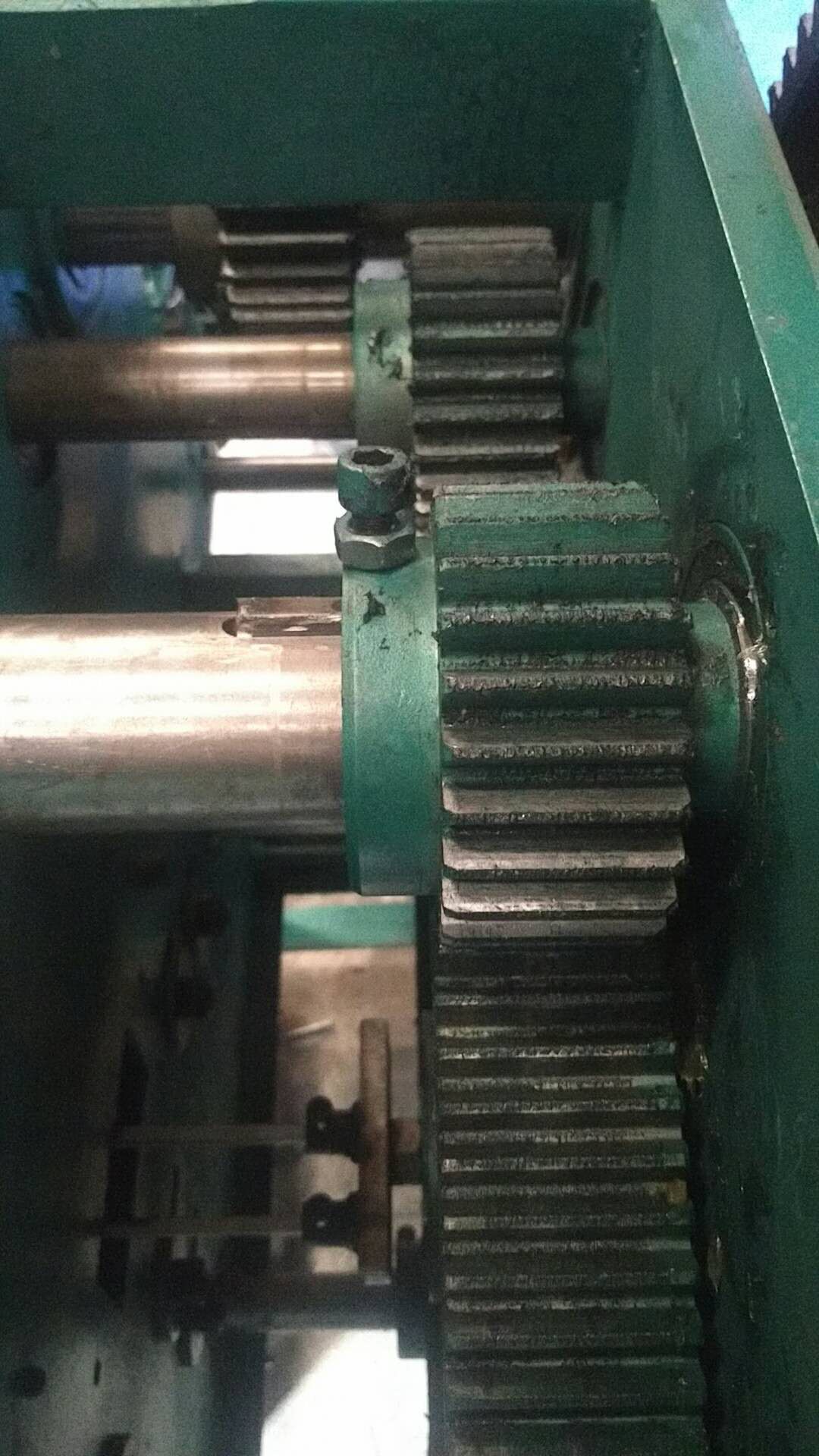

Customer: there is one screw loose and the machine becomes out of sync

After service engineer: please turn the big belt wheel at backside without feed the steel strip and take a video to show me

Customer:Sir,All gear position are disturb

After service engineer:check the cam at the bottom of the machine and see whether it is loose or tight

Customer::

All bolts are tight now.

After service engineer:

please check the cam at the bottom of the machine and if it is loose please fasten it by screwing it tight (by hammer you can tighten the screw of the cam)

any gear fall down before?

Customer:

Yes,

Actually during running of the machine, one of the gear is in out of the position due to loosen the bolt.

After service engineer:

which one has fallen down? is the bottom shaft gear?

Customer:see this one has become looose before

After service engineer:

can you take out the two square keys which push the steel strip and put the steel strip inside and move the big belt wheel and take a video?

uncrew the two screws of the square keys at backside and get out the two square keys ( you see from the the front the two keys)

Customer:OK

After service engineer:stop!!! do not put on power

just move by hand otherwise it would damage the machine!

first let one person move the belt wheel until it move to the position of the cutter and hold on that position without moving the belt wheel

second step, uncrew the shaft's gear and lever the small gear out from the big gear paying attention without getting out the small square key inside

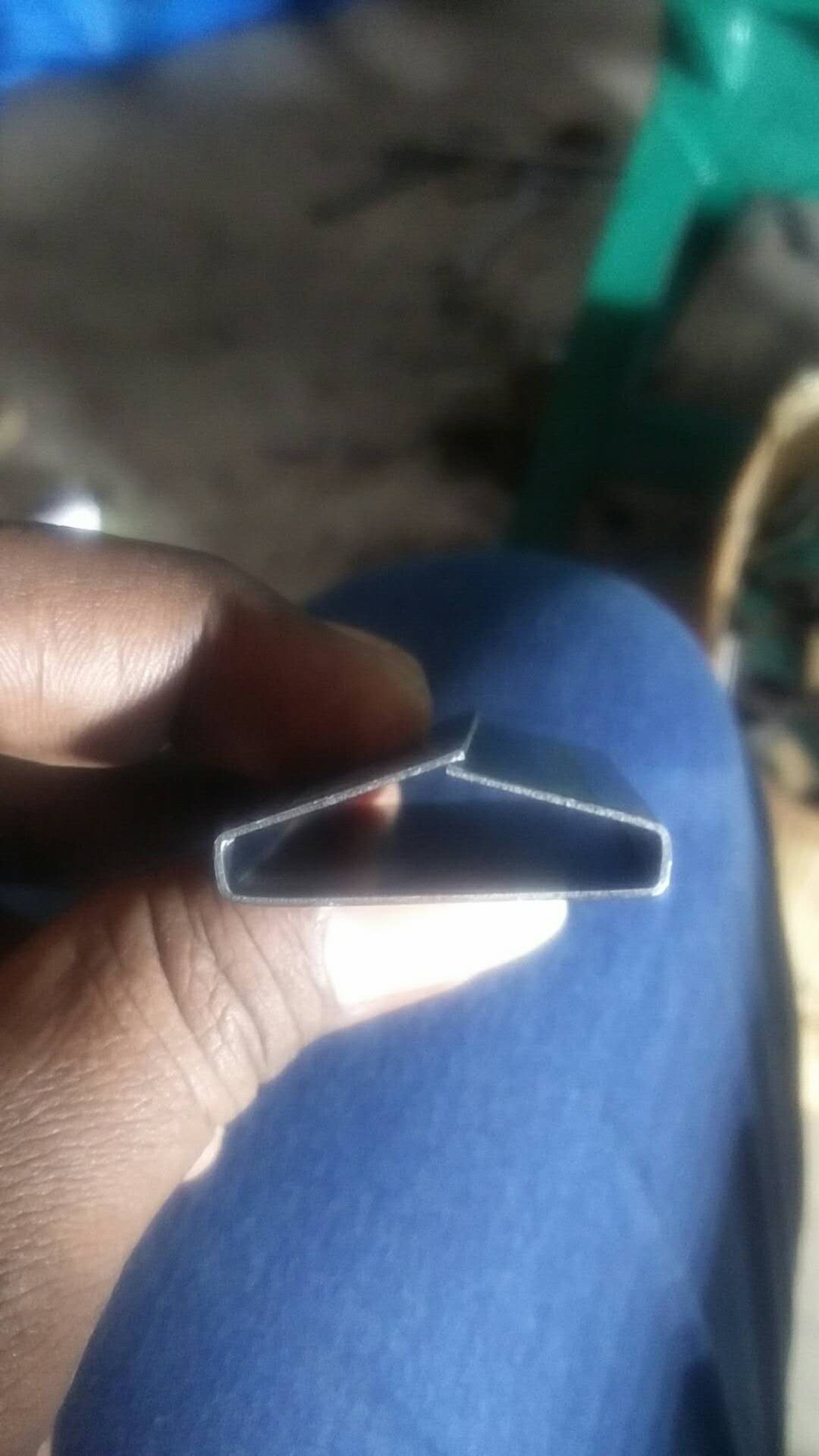

third step, move the cam at bottom after its screw being unscrewed and turn it to the "0" beginning position and it makes the pushing bar just push

until to the central core's position

fourth step, , move the big wheel until it goes to the postion of cutter (in below photo)

fifth step, put the small gear back to the postion with big gear again and take a video of moving big belt wheel

Customer: OK we'll do it and take video to show you

After service engineer:yes

Customer: you see

After service engineer: please put the two square keys back to the position and take video after that with hand moving the belt wheel !!

Customer: yes we'll put on the two keys

After service engineer: OK first turn the wheel manaully and to see the forming of the seals with steel strip fed into the machine

Customer:OK

After service engineer: yes

Customer:: Less overlapping

After service engineer: Please let one worker turn the belt wheel until it stop at the position of cutter and t ake a photo or video of it at the back side of the machine

Customer: OK here it is

After service engineer they are correct without problem

unscew the screw and let the block move righ side a littile bit

and hit the block a little big to the right side( just a little)

After service engineer Now it is OK

Customer:How to eliminate back side scretches?

After service enginee: this can not eliminate during the process of shape forming

Customer OK thanks

After service enginee:please adjust first with hand moving the belt wheel for the safety of the machine and after everything is OK you turn on the power

Customer ![]()

Get quick quotation by WhatsApp: +85362802153