Customer from African country has faced the problem of out of sync after their adjustment of machine

customer: it goes out of sync now

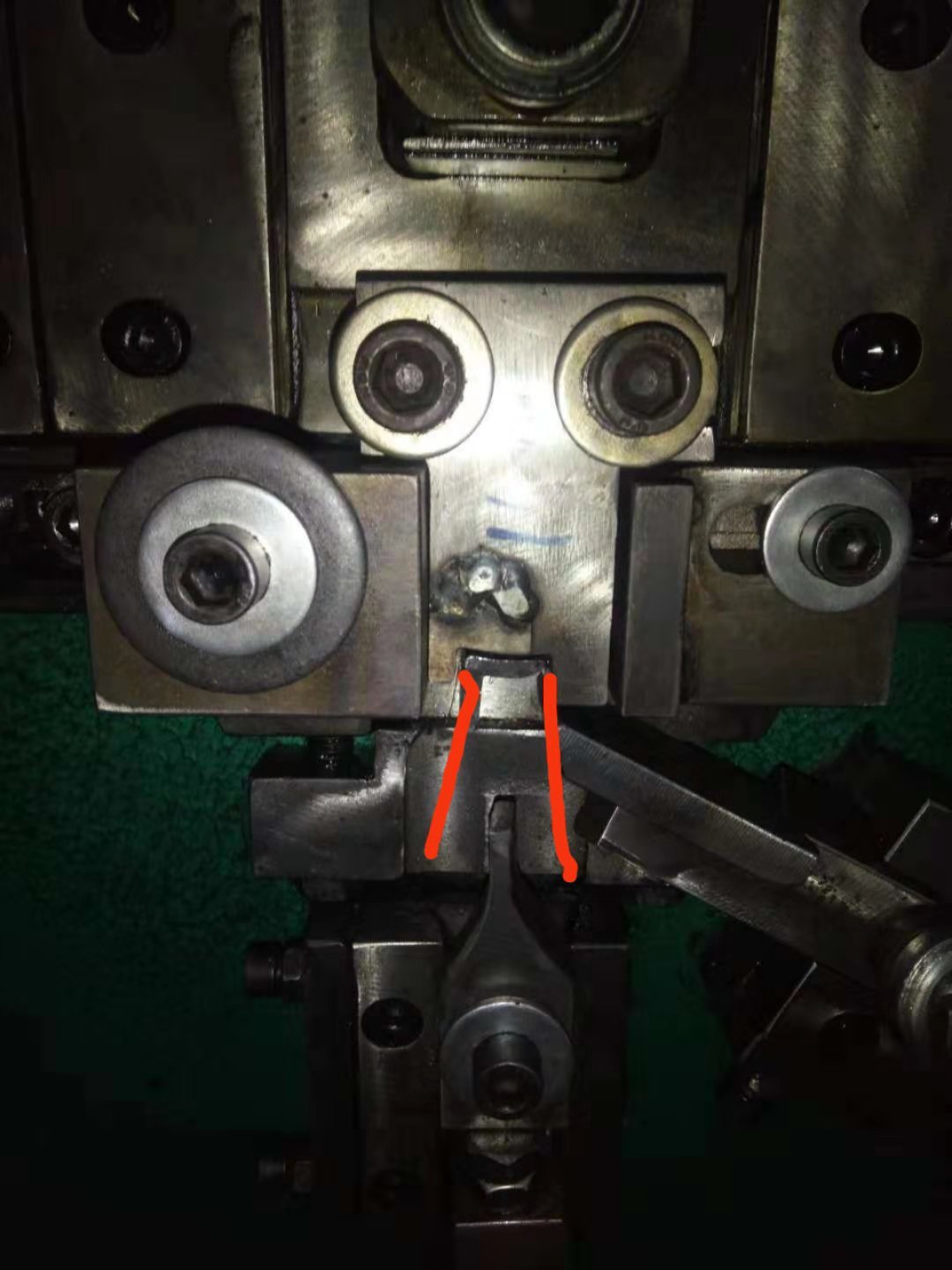

after service engineer: the gap in cutting is too small, colin:

can you move the mold to the left side and kee the the same gap between left and right

customer:we make the gap smaller

after service engineer:there must be no gap nearby the cutter. like you use scissors there must be no gap when cut other wise you can not even cut a paper

close to the cutter

close to the cutter

keep closer and tight to the cutter

the left side gap which is important for making the "L" shape of the PET-strapping clip-to keep it 90 degree angle. and the right side gap fix the shape of wrapping up

customer:How to adjust this tighter?

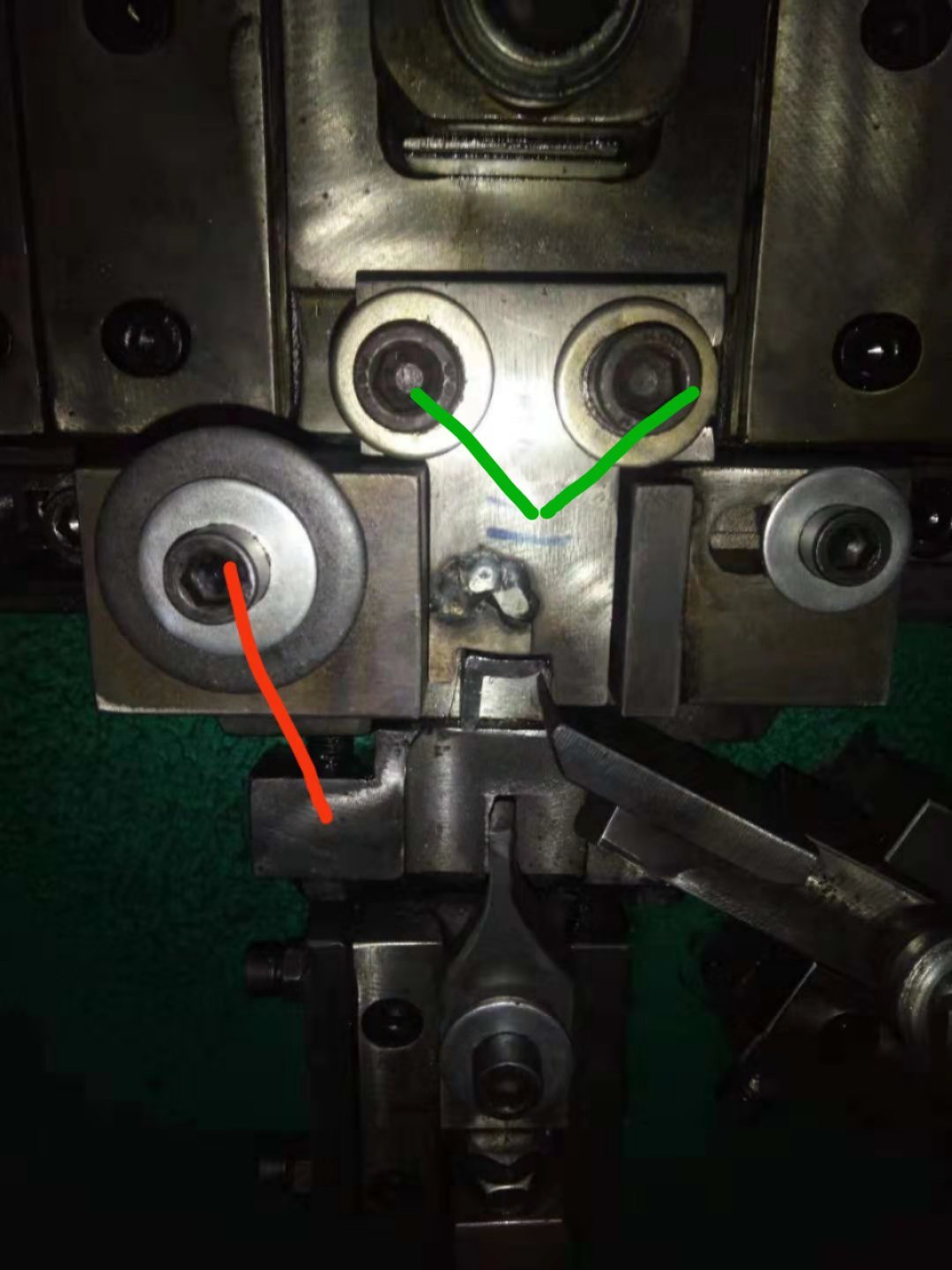

after service engineer: make the screw loose at red line

and push the cutter after that fix the screw tight again

loosen this screw in red mark line

customer:this one ?

after service engineer:yes

watch the video please

customer: Ok which screw is to be unscrewed first?

after service engineer:the lower part two screws

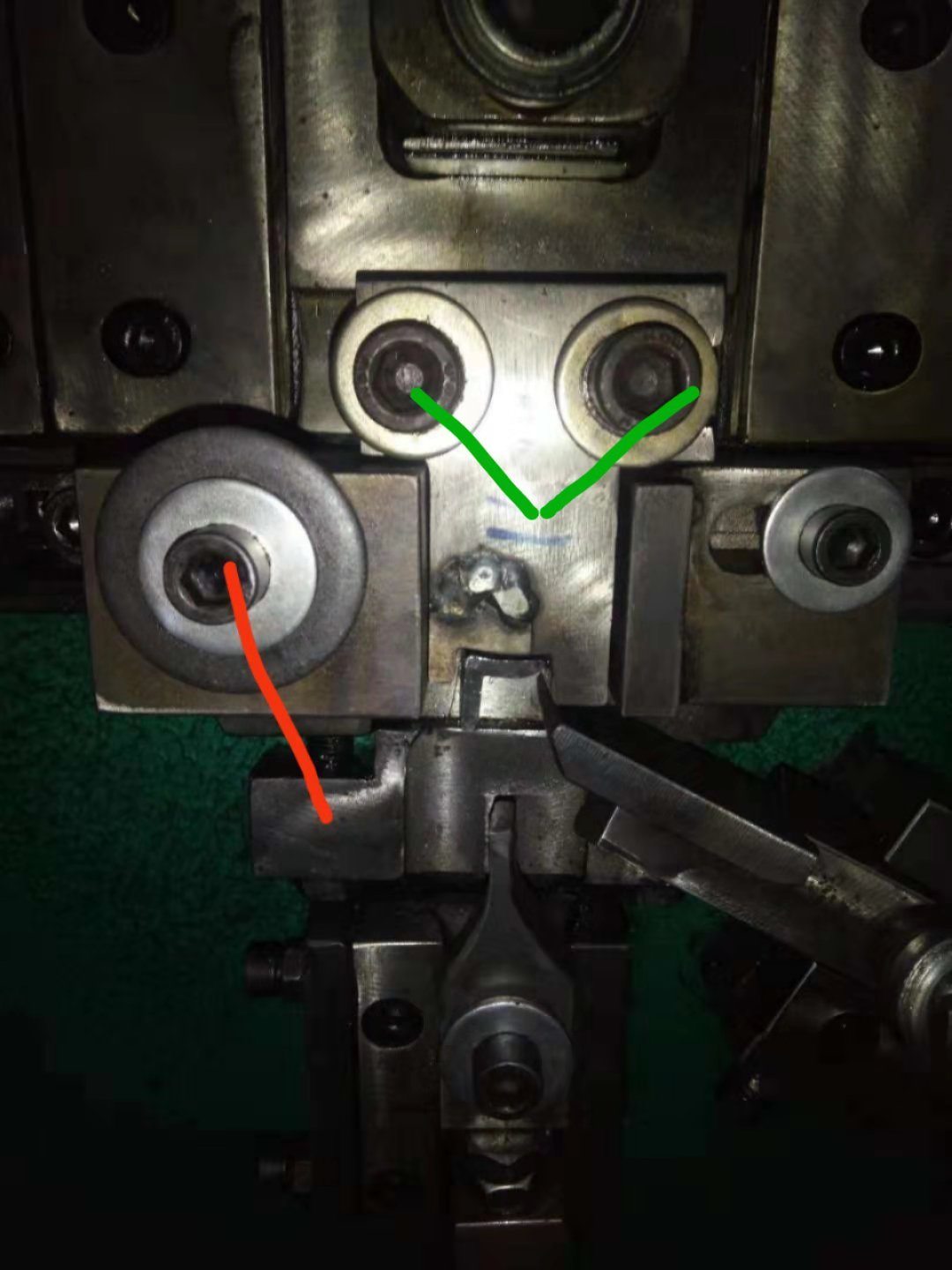

loosen the green two screws first after lossening you push it up and then fix the screw again make sure it is tight upward

customer:So this screw we no touch

after service engineer:

(1) loosen the two green screws (2) push it upward tight (3) fix the two screws again (4) loosen the big red screw (5) push it to right side and fix the screw again

last step is loosen the red screw and push the steel parts to the right side and tighten the screw again

customer:OK Colin I work with your instruction. If can do detailed video would be very much help to make sure we get right.

after service engineer:OK

customer:From video you send I think something no align properly. I send picture and video for you to see

after service engineer:we send the instructions of how to adjust

customer: we do and this now happen

after service engineer:listen please

after service engineer:Please do as following video

and then next video

customer:please translate

after service engineer:

translated one

translated two

if you would have done first two things correctly then there sould be no problem

(1) turn the belt wheel to the cutter postion and stop\

(2) turn the small gear's cam until it push up upper part closely

(3) put small back into the big gear and bite each other

(4) turn the belt wheel to check the sync problem is solved or not

customer: OK

after service engineer: if the rigt side shaft hit, please adjust the gear of right side shaft until it won't hit again

customer:OK

after service engineer:next video

customer:I look through now

after service engineer:OK

customer:does this look correct now

after service engineer:ok

customer:OK we win thank you team

after service engineer:

(1) did you forget to fix the screw tight at the small gear? (2) please check the small or big gear whether there is something broken in the gear teeth

(3) check the case of out of sync happened in whch shaft and check the shaft's screw is firmly fixed or not

customer:Is video above alright

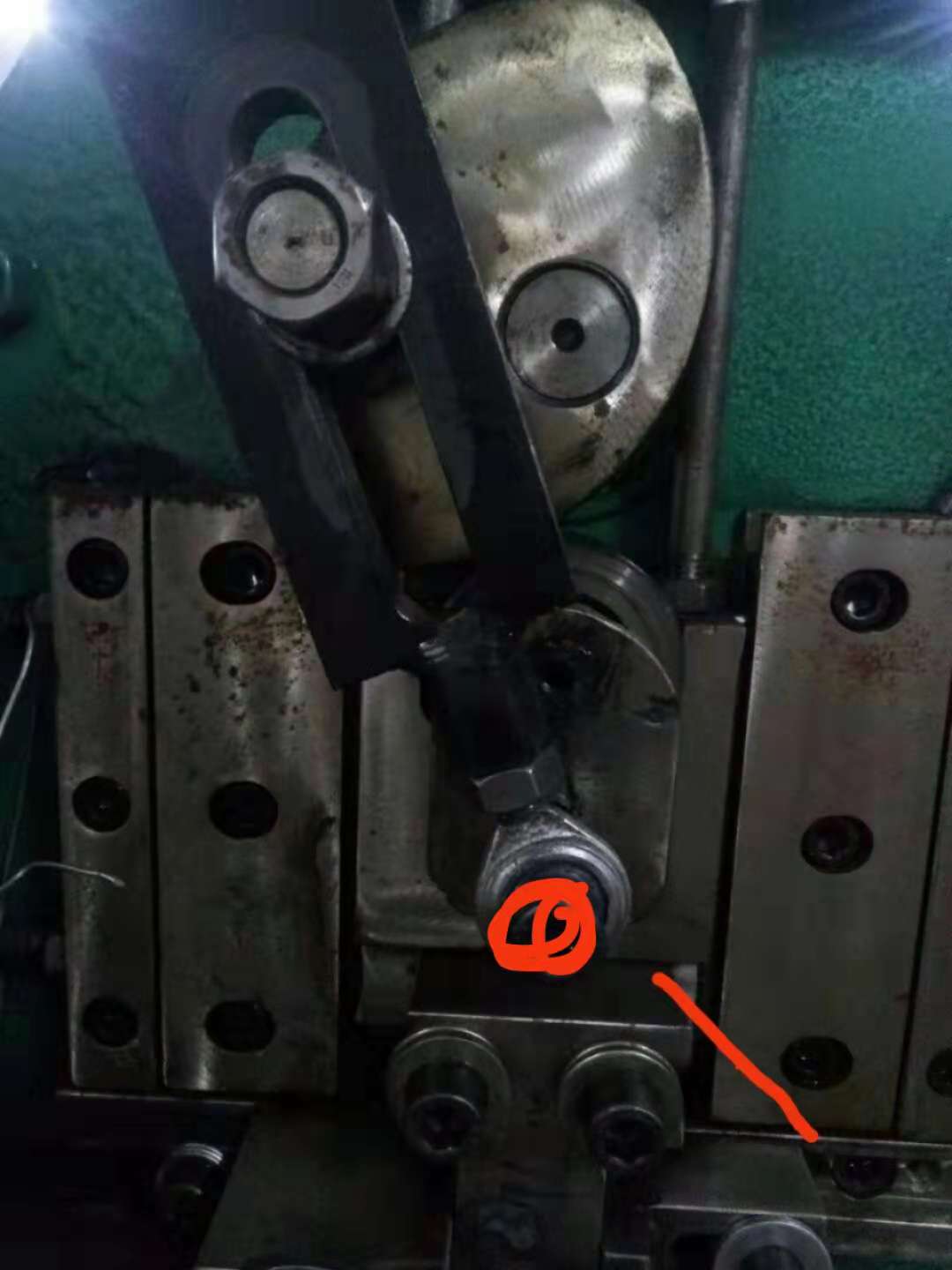

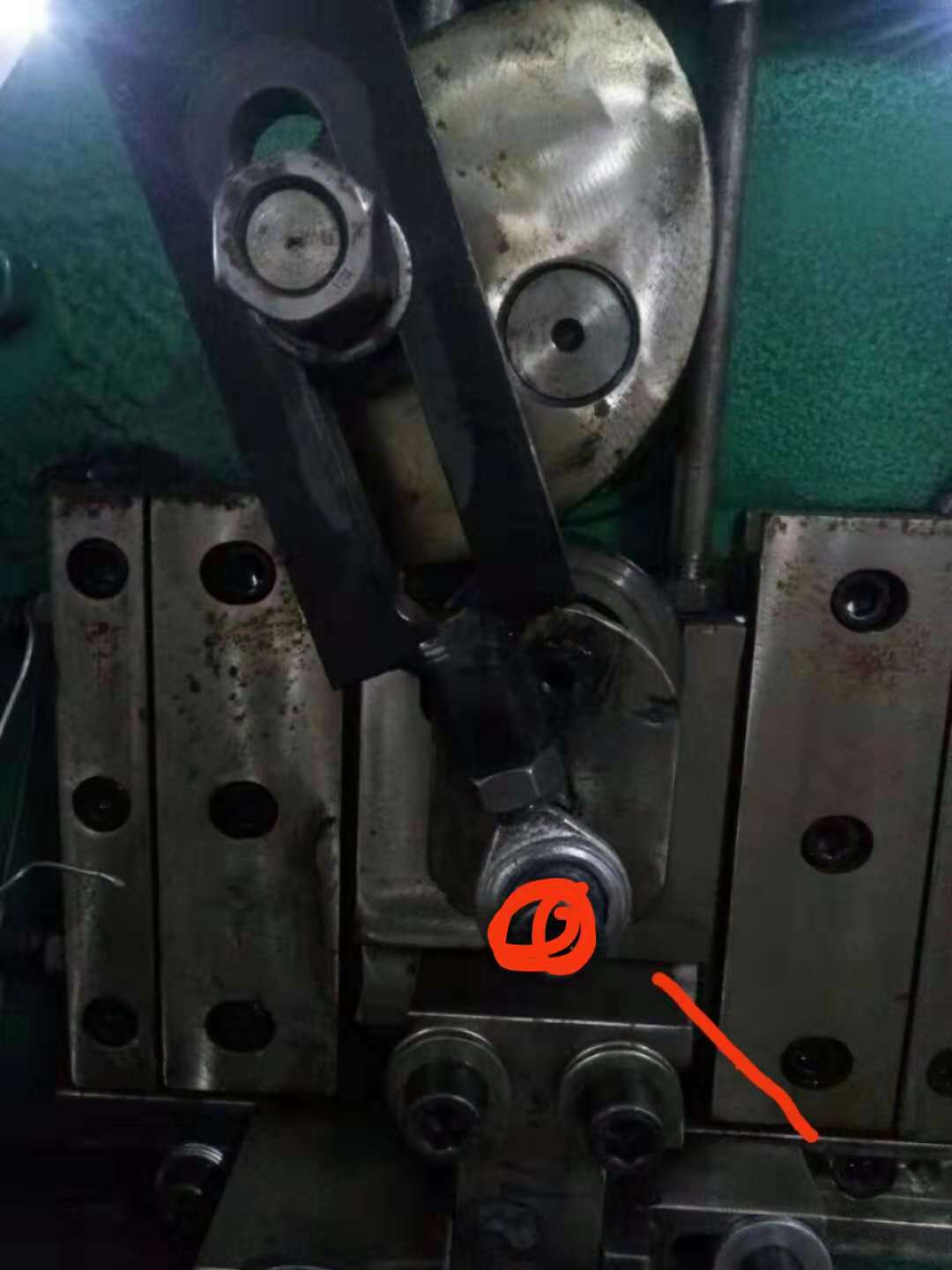

after service engineer:the bottom shaft's gear is out of sync

customer:Is this the gear?

after service engineer: the photo above is for adjusting the feeding and timing of feeding.

customer:OK

after service engineer: check the video sent now

(1) unscrew the bottom shaft's gear (2) adjust to the position of cutter (3) fix screw again after the cam is turned to the position in the video

customer::

We do this already many times and it no change feed

after service engineer:

your video is to change the feeding

this is the gear which is lack of one or two gear teeths from your video's presentation

firstly you adjust the bottom gear for the correct positin and after that you may adjust the feeding if needed

customer:OK

after service engineer:check below video

please check the video again that you have to adjust the bottom shaft's gear to the cutter position before the cutter cuts otherwise it will affect the shaping and also it will hurt the central flat steel

now from your video that the cutter first cuts before bottom gear come up which is wrong

the bottom gear should first come up and support the central flat steel before the upper come down and cut it off

customer:Please check video

after service engineer:

two gears move earlier than needed

pleaes back down one gear's teeth

too earlier it moves now

customer:Please check

after service engineer:new video is OK

customer:But not feed properly

after service engineer:wait and send you the video for feeding

(1) two men work together

(2) first uninstall the feeding screws

(3) another person turn the belt wheel to the position as shown in the video

(4) hold on the belt wheel ( sometimes it moves if no control)

(5) fix the screws back to the position again

customer:OK we do but still not feed Does grip part have anything to do with feed

after service engineer:please take a whole picture or video when you or someone turn the big belt wheel so check anything wrong with it (overall view)

customer Here you see wheels are turning but metal no move because grip has already moved up

after service engineer: please take a wider view of video like this video when you turn the belt wheel

customer OK here is the video:

after service engineer:Check the video below

and

(1) first unscrew the two screws and take out the squre key (2) then unscew the other two screws

in the latest video you see the small gear moves in correct dicrection and please loosen the small gear's screw and lever the the gear out and turn the gear in opposite direction with six teeth movements and finally put the gear

back to postion and fix it tightly and after that please take a video with some one turn the belt wheel again (wider view)

customer :ok check

after service engineer: please follow the instruction and take the two square keys out first

customer So I leave the piece loose?

after service engineer:take them out

customer:OK

It now feeding

now how to align this part

after service engineer:now is correct and give video for the installing the two keys

first photo is to show the correct position for the belt wheel turning

second photo is to show tight the screw at that position

in the video (1) turn belt wheel until it move at the top place of two square keys(it does not touch two squre keys) (2) the triangle part is to fix the screw when it is at the position of down slope (3) finally you turn and install the two square keys back to their position again

customer OK we will try and send you the final video

after service engineer:please take a note of all that adjustment if you have time and send to us and will reivise it and send to you for your future maintenance

customer: ![]()

🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀