Composite cord strapping is designed as one of the best alternative to metal strapping.

When used with buckles, composite strapping provides you the strongest and most reliable joint. In fact it is considered the most durable joint in the strapping industry.

The machine which produces the buckles are very important in the whole industry line which need to be fast, cost effective and safe + stable.

our buckle machine provides the solution to the needs of customers.

Specification:

specification for strapping buckle 13 machine ![]()

specification for strapping buckle 16 machine ![]()

specification for strapping buckle 19 machine ![]()

specification for strapping buckle 25 machine ![]()

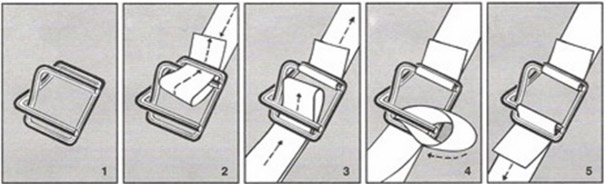

The buckle is used to fix the pallet and the loads and to connect the two ends of the strap during the application of the strap. Buckles are also referred as wire buckles.

The quality of the buckles is the most important factor affecting strength of the joint of the strap. The quality of the buckles depends on the diameter of the wire, the quality of the wire used, the quality of the surface coating and the form of the buckle.

Cord-strapping buckles are mainly used with Polyester Corded Composite Strapping, Textile (hotmelt) Strapping and Woven Polyester Strapping Strapping but are also used with PET Strapping and PP Strapping.

Cord-strapping Buckles, are produced in two different surface qualities: Phosphate coated and Galvanized Buckles.

| Product Code | DIMENSION | Wire Diameter | In-Box Quantity |

|---|---|---|---|

| COB4G13 | 13 mm | Ø 3,0mm - Ø 3,3mm | 1000 pieces |

| COB5G16 | 16 mm | Ø 3,3mm - Ø 3,5mm | 1000 pieces |

| COB6G19 | 19 mm | Ø 3,5mm - Ø 3,8mm - Ø 4,0mm | 1000 pieces |

| COB8G25 | 25 mm | Ø 5,0mm - Ø 6,0mm | 500 pieces |

| COB10G32 | 32 mm | Ø 7,0mm | 250 pieces |

The quality of the buckle is one of the important parameters that determine the system strength of the strap. The most important factor affecting the system strength is the strength of the Joint.

The System Strength of the Polyester Corded Composite Strapping is a very important parameter in terms of securing the package. As an example, for Composite strapping, its system strength should be more than 60% of its Linear Breaking Strength.

| Product Code | Coil Length (m) | Breaking Strength | System Strength |

|---|---|---|---|

| CS34STR | 400 M | 1500 daN | 2400 daN |

The wire used to produce wire buckle is phosphate coated and that is why they are referred as such.

They are used with Cord-strapping Polyester Corded Textile (hotmelt) strapping and Cord-strapping Polyester Corded Woven Polyester Strapping strapping applications. Thanks to the roughness of the wire surface, they are more compatible with these types of straps.

The wire used to produce Wire Buckle is Galvanized and that is why they are referred as Galvanized Buckles.

Cord-strapping Galvanized Buckles are used with Polyester Corded Composite Strapping and Polyester Corded Hotmelt (Textile) Strapping. They are also used with PET Strapping and PP Strapping applications. Although the System Strength of PET Strapping & buckle and PP Strapping & buckle combinations are not as strong as Composite Strapping & buckle combination, for light applications PET Strapping and PP Strapping are used manually with a Galvanized Buckle due to its ease of use.