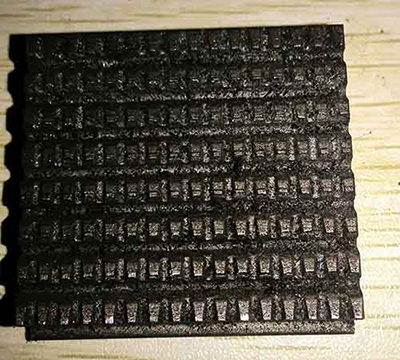

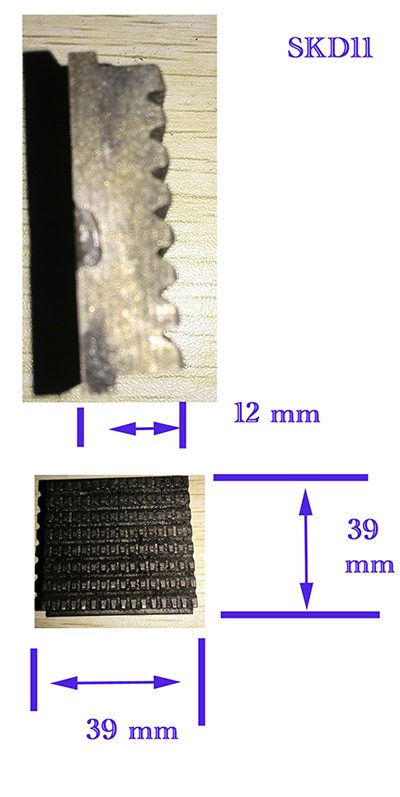

SKD12 is an air-quenched die steel with deep air-quench hardening performance, which is extremely beneficial for complex molds that must maintain their shape after quenching and tempering. The deformation of this steel due to air quenching is only about 1/4 of that of manganese oil-quenched tool steel. The wear resistance is between manganese and high-carbon and high-chromium tool steels, and its toughness is better than any one. It is suitable for tools that require good wear resistance and special toughness. It is widely used in blanking dies and forming dies, rolls, punches, calendering dies and thread rolling dies, as well as some types of scissors blades. .

Chinese name SKD12 die steel grade SKD12 die steel grade advanced cold work die steel heat treatment hardness 58-61HRC implementation standard JIS G4404: 2000

It is suitable for various hardware cold punching dies, and large and complex punching dies that can withstand greater impact.

Factory stateedit

Spheroidizing annealing HB≤230

C: 0.95/1.05

Mn: ≤1.00

Si: ≤0.50

Cr: 4.75/5.50

P: ≤0.025

S: ≤0.020

Mo: 0.90/1.40

V: 0.15/0.50

1. Air quenching die steel has deep air quenching hardening performance,

2. High wear resistance, slight deformation, high hardenability, high compressive strength,

3. The carbide distribution is more even than that of Cr12 steel.

Annealing: 1, 800-850oC slow cooling 2, spheroidizing annealing process

Quenching: 940-960oC air cooling

Tempering: 180-220oC air cooling HRc=60-64 510-520oC air cooling HRc=57-60

The critical temperature of SKD12 steel is shown in Table 2-4-2, the density is 7.84t/m³;

the mass constant pressure heat capacity cp is 460.55J/(kg·K); the elastic modulus is 203000MPa.

🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀 🍀